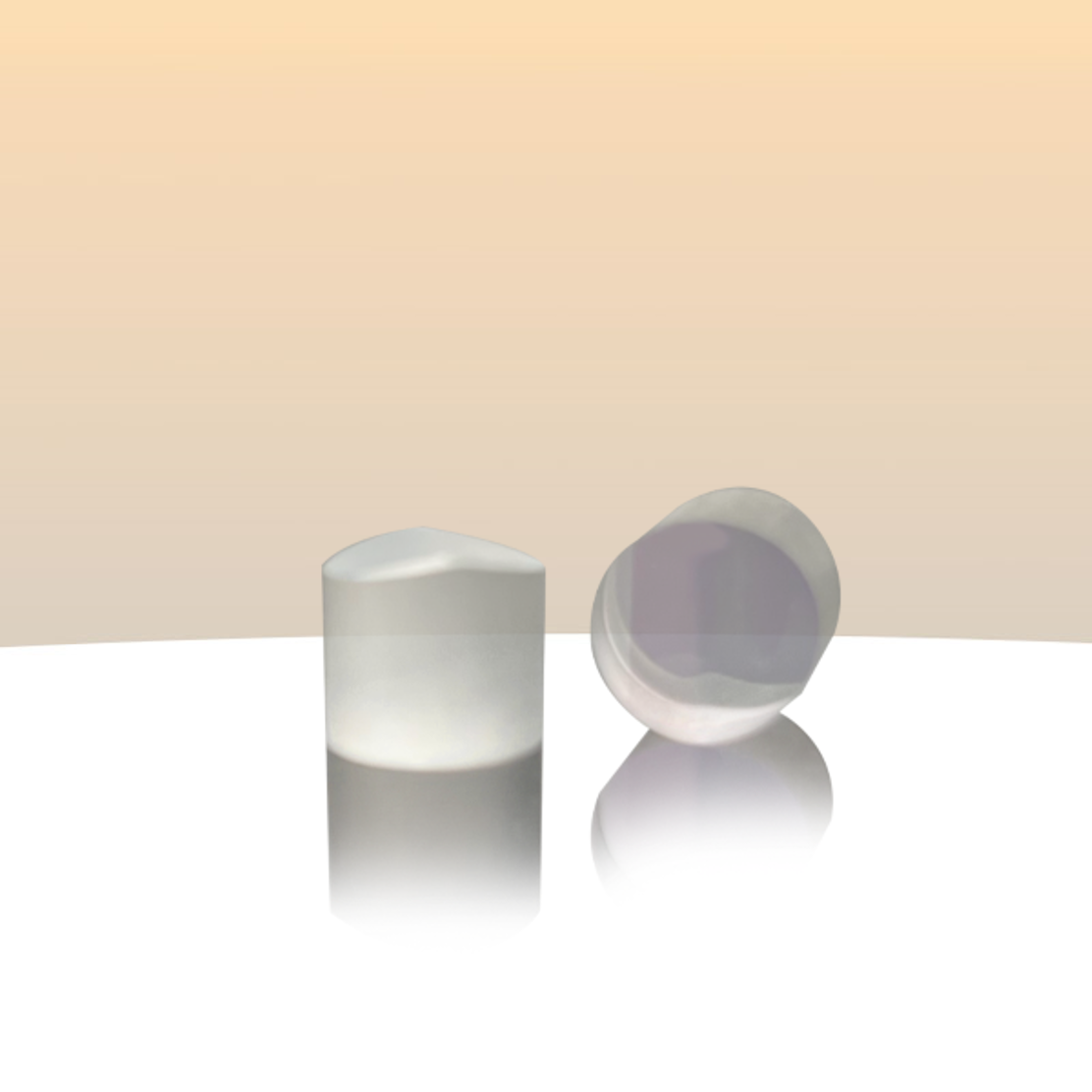

Powell prisms

Powell prism is an optical scribing prism, which enables the laser beam to be optimally scribed into a straight line with uniform optical density, good stability and good linearity after passing through. Powell prism scribing is superior to the scribing mode of cylindrical lenses, eliminating the central hot spot and faded edge distribution of Gaussian beams.

When a Gaussian laser beam passes through an ordinary cylindrical lens, it will produce unevenly distributed straight lines, while the top of the Powell prism is a complex two-dimensional aspheric surface. When the laser passes through, a large amount of spherical aberration will be generated, redistributing the light path and reducing the central area. The light at the edge is increased to form a uniform straight line, which is suitable for various machine vision applications such as biomedicine, automobile assembly, and food processing.

Powell prismsDescription

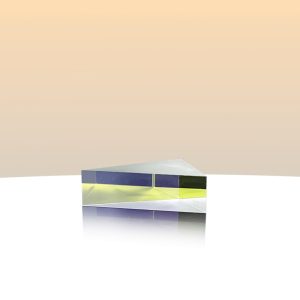

Fan angle of Powell prisms

The fan angle width is a function of the refractive index of the glass and the vertex angle. The higher the slope of the top, the higher the refractive index of the glass, and the larger the fan angle for the same projection distance. Small fan angles usually use optical glass with refractive index n=1.5, and large fan angles usually use high refractive index glass with n=1.8, or increase the top tilt angle.

Available in stock are 6mm and 8.9mm diameter prisms with fan angles of 1°, 5°, 10°, 15°, 20°, 30°, 45°, 60°, 75° , 90°. Accept customer customization requirements, design and manufacture special application prisms, and the one-time design cost is also very low.

Laser beam size In the case of a certain projection distance, the size of the incident laser beam determines the thickness of the laser line. A parallel laser beam with an elliptical cross-section may produce two straight lines, either wide or narrow.

In the direction of the incident light, the main axis of the laser is parallel to the top of the prism, and the narrow laser incidence forms a small depth of field. Wide incident light direction, the laser axis is perpendicular to the top of the prism, and wide laser incidence forms a large depth of field. The beam is focused on a CCD array with a working distance of 500mm under different conditions. The following figure clearly shows the difference between the laser beams in different incident directions and after beam expansion through the prism to form a straight line. The spot size on the exit plane is the obvious difference.

Uniformity

The performance of the Powell prism is determined by the characteristics of the incident laser light and the quality of the aspheric surface of the lens. Reasonable selection of the prism matching the laser module can produce uniform laser lines and meet high-demand applications.

Light intensity distribution

For a uniformly illuminated laser line, the light intensity contained in the central 80% of the length should account for more than 80% of the overall intensity. If the energy occupied by the middle part is too low, the brightness at both ends will increase, and reducing the brightness at both ends will help improve the overall utilization efficiency of the laser. difference.

The Powell prism provided by 1T Optics, the central area of the straight line accounts for 80±5% of the light intensity, and the uniformity is very good.

Laser Line Straightness and Accuracy

The straightness and aperture deviation of the straight line depend on the manufacturing quality of the prism and the precision of the laser module installation. If the laser is not incident perpendicular to the prism, line curvature will occur, and an aperture error will be created between the wedge-shaped top and bottom exit surfaces of the prism, resulting in a shift away from the target position. If the prism is installed correctly, the wedge-shaped apex of the prism is only slightly tilted, and the resulting line curvature is also very small.

The aperture deviation of the Powell prisms we provide is less than 3mrad, measuring 80% of the length of the straight line, and the straightness deviation is less than 0.1%.

Prism Mounting Options

The laser beam width determines the performance and physical properties of the prism. The most significant difference is the position of the divergence angle on the exit surface. It must be ensured that the divergent beam does not exceed the lens size.

The non-uniform distribution of the beam passing through the non-linear spherical surface of the prism will be generated, so the appropriate prism should be selected according to the diameter of the laser beam, and the exit plane at the bottom of the prism should be larger than the beam cross section on this plane. Standard 90° prisms are only suitable for beam expansion of wide-incidence lasers.