Front surface mirror / Fist surface mirror

The front surface mirror is an optical element that reflects the incident light by coating a layer of metallic silver (or aluminum) thin film on the back of the optical glass by vacuum coating.

Front surface mirror / Fist surface mirrorDescription

The use of a high reflectance mirror can double the output power of the laser; and it is the first reflection surface reflection, the reflected image is not distorted, and there is no ghosting, which is the reflection of the front surface. If an ordinary reflecting mirror is used as the second reflecting surface, not only the reflectivity is low, the wavelength is not selective, but also ghost images are easily generated. The use of the coated mirror, the obtained image is not only high in brightness, but also accurate without deviation, clearer in image quality and more realistic in color. Front surface mirrors are widely used for optical high-fidelity scanning reflection imaging.

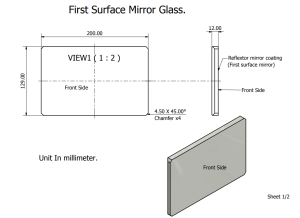

1, Substrate: Float glass or Fused silica

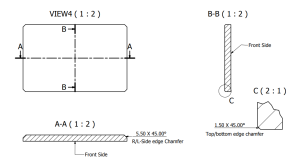

2, Dimension: Upon customers’ request

3, Standard thickness: 0.5mm, 0.7mm, 1.1mm, 1.25mm, 1.9mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm

4, Coating: Metal Al Coating7, Film test table

5, Reflection rate:

| Item | Reflection @ wavelength | Application |

| HR94 | Ravg>94@ Visible wavelength (general imaging standard) |

Scanner, Copier, PTV, OHP, etc. |

| HR97 | Ravg>97% @ a certain color light wavelength | Scanner, PTV, LCD Projector,

etc. |

| HR98 | ||

| HR780-A | Ravg>97% @ NIR wavelength | LBP(Laser Beam Printer) or other OAdigital Products |

| HR780-B |

6, Actual test reflectivity @400nm-700nm, AOI=45°

| Wavelength | Minimum reflectivity |

| 400nm | 92.0% |

| 450nm | 95.5% |

| 500nm | 95.5% |

| 550nm | 94.5% |

| 600nm | 92.5% |

| 650nm | 92.0% |

| 700nm | 90.0% |

7, Film test form

| Pilot item | experiment method | judgement standard |

| Stickiness

|

Tape No.600 made by 3M Scotch is firmly attached to the film side of the surface, and then the tape is quickly removed.

|

There is no peeling of the surface mirror film or abnormal fouling in appearance. |

| Wear resistance

|

A cylinder with a load of 500g and a diameter of 50mm is wrapped with three pieces of cotton cloth, soaked with alcohol, and then reciprocated on the surface mirror film 300 times at a certain speed.

|

There is no peeling of the surface mirror film or abnormal fouling in appearance. |

| Moisture resistance

|

Place the surface mirror in an environment with a temperature of 50°C and a humidity of 95%, and then let it stand for 24 hours.

|

There is no peeling of the surface mirror film or abnormal fouling in appearance. |

| Corrosion resistance

(salt water spray)

|

The surface mirror was placed in an environment with a temperature of 35 °C, sprayed with a 5wt% NaCl aqueous solution, and then allowed to stand for 24 hours.

|

There is no peeling of the surface mirror film or abnormal fouling in appearance. |