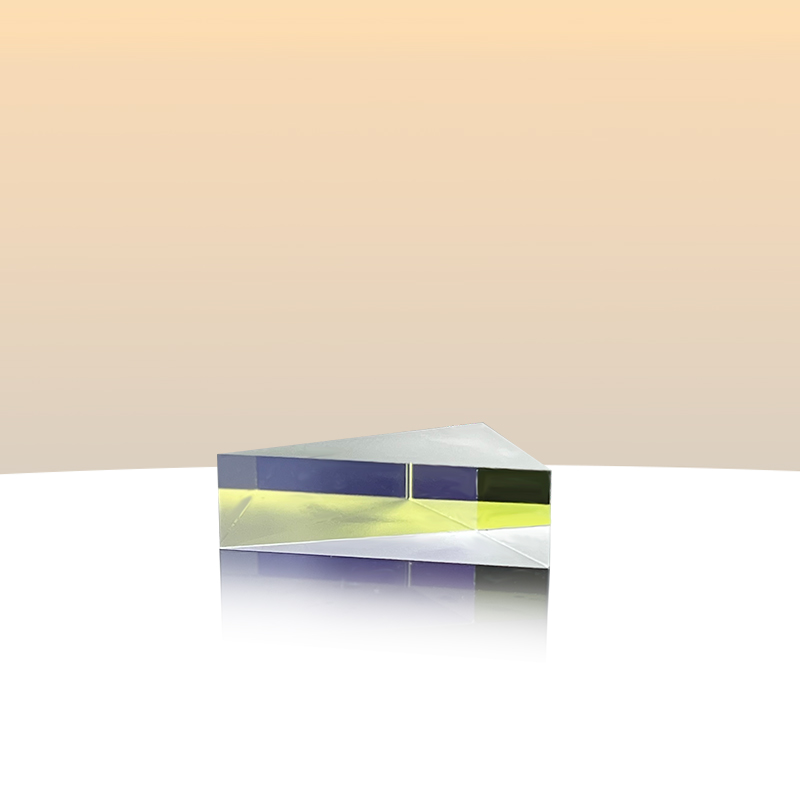

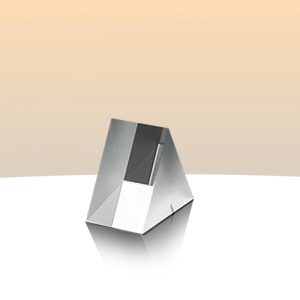

Right angle prisms

By far, the most commonly used prisms are 45°-90°-45° prisms, commonly known as right angle prisms. It can achieve different results related to image parity or bias in a number of ways, so named because of the angles on its triangular faces. The most common application for a 45°-90°-45° prism is to think of it as a right angle prism, which has only one reflection that deflects the incoming ray by 90°. The resulting image will become left-handed, but can be reversed or restored depending on the position of the prism.

Right angle prismsDescription

Right-angle prisms can achieve 180° and 90° rotation of light through the internal reflection of right-angle surfaces or inclined surfaces. They are widely used in imaging systems, and high-precision right-angle prisms are also very suitable for the laser industry.

0.5mm microprism or 100mm microprism can be customized according to customer needs.

|

Specifications |

|

| Material | N-BK7, H-K 9L, Fused silica, or Custom |

| Dimension | 3mm – 200mm |

| Dimension tolerance | ±0.05mm to ±0.1mm |

| Clear aperture | >85% – 90% of dimension |

| Angle tolerance | 5 arc sec. to 3 arc min. |

| Surface quality | 60/40, 40/20, 20/10, 10/5 scratch/dig |

| Surface accuracy | λ/10 to λ (@632.8nm) |

| Transmitted Wavefront Error (TWE) | λ/10 to λ |

| Bevel | 0.1mm to 0.25mm |

| Coating | Anti-reflection (AR) Coating, Metal reflection coating, Dielectric coating. |