Laser Galvanometer / Laser scanner Mirror

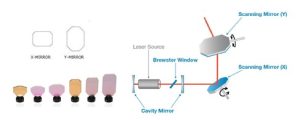

The principle of the galvanometer is: input a position signal, the swing motor (galvanometer) will swing a certain angle according to the conversion ratio of a certain voltage and an angle. The whole process adopts closed-loop feedback control, which is composed of five control circuits, such as position sensor, error amplifier, power amplifier, position discriminator, and current integrator.

Laser Galvanometer / Laser scanner MirrorDescription

Laser scanners are also called laser galvanometers, which consist of X-Y optical scanning heads, electronic drive amplifiers and optical mirrors. The signal provided by the computer controller drives the optical scanning head through the driving amplifying circuit, thereby controlling the deflection of the laser beam in the X-Y plane.

In the laser demonstration system, the waveform of the optical scanning is a vector scanning, and the scanning speed of the system determines the stability of the laser pattern. In recent years, high-speed scanners have been developed that can scan at speeds of up to 45,000 points/second, thus enabling the demonstration of complex laser animations.

In short, the galvanometer system is a high-precision, high-speed servo control system composed of a drive board and a high-speed swing motor. It is mainly used for laser marking, laser engraving, stage lighting control, and laser drilling.

Advantage:

- Fastest motor speeds in the industry, delivering low drift and long-term stability

- Superior precision and accuracy that ensure high-quality scanning output

- Extensive range of aperture sizes and mirror coatings

- Compact models with small footprint ensure easy integration for small spaces

- Broad range of product offerings from high-performance to cost-effective

Specification

- LXW Tolerance: +0/-0.1

- Clear Aperture: >90%

- Thickness Tolerance:+/-0.1mm

- Surface Quality:40/20

- Surface Figure: lambda/425mm2(at)632.8nm